Tel:

Email:

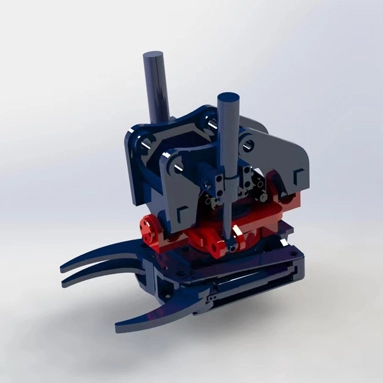

A vibro ripper is a specialized attachment used in construction and excavation machinery, such as excavators, designed to efficiently break up hard or compact materials like rock, frozen ground, or asphalt. Here's a detailed breakdown:

1. Vibration Technology:

Integrates high-frequency vibrations (typically hydraulic-powered) with traditional ripping action. The vibrations reduce friction and material resistance, allowing the ripper to penetrate and fracture surfaces more effectively.

2. Design:

Consists of a shank or tooth that penetrates the ground, often paired with a vibratory motor. The vibration is usually concentrated near the tip to maximize material disruption.

3. Hydraulic Power:

Utilizes the host machine's hydraulic system to generate vibrations, enabling adjustable frequency and force for different materials.

Construction: Trenching, site preparation, and demolition.

Mining/Quarrying: Breaking rock or extracting minerals.

Roadwork: Removing asphalt or frozen surfaces.

Utility Installation: Precise digging in challenging soils.

Eco friendly and noiseless, ideal for works on urban location

Workable in frozen earth(-20°) and under water conditions without extra air conditioner.

Bucket tooth and wear-resistent tips is optional

Double motors and double vibrate cases increase the vibrate power

All main components is famous brand which assure high quality.

3 – 5 times higher productivity than a traditional breaker

English

English Deutsch

Deutsch Español

Español русский

русский português

português العربية

العربية