Tel:

Email:

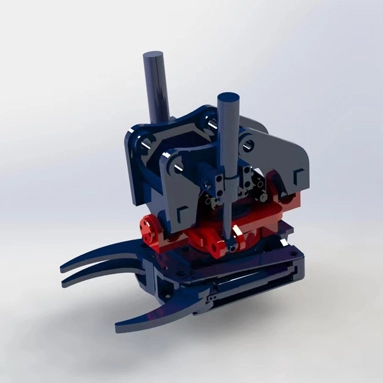

1, In addition to two hoses, our hydraulic magnet features a cable that connects directly to the excavator’s 24V external power source. This allows for immediate control of the magnet’s magnetization and demagnetization, enabling instantaneous magnetic engagement or disengagement.

In contrast, other brands of hydraulic magnet, which lack this external power connection and rely on hydraulic pressure to convert into electrical control. This process takes approximately 4-5 seconds, meaning it requires 4-5 seconds to achieve magnetization or demagnetization. This has significantly diminished work efficiency.

2, The lifting capacity of the hydraulic magnet is rated and primarily determined by the motor’s power and the number of coils (the larger the diameter of the suction cup, the more coils it contains).

Additionally, the magnetic field and the surface area of the object being lifted effect the lifting capacity of the hydraulic magnet. For instance, a whole iron sheet compared to a pile of small iron scraps—undoubtedly, the hydraulic magnet can lift the entire iron sheet more effectively. A hydraulic magnet with a diameter of 1200mm can lift an entire iron sheet weighing 7-8 tons.

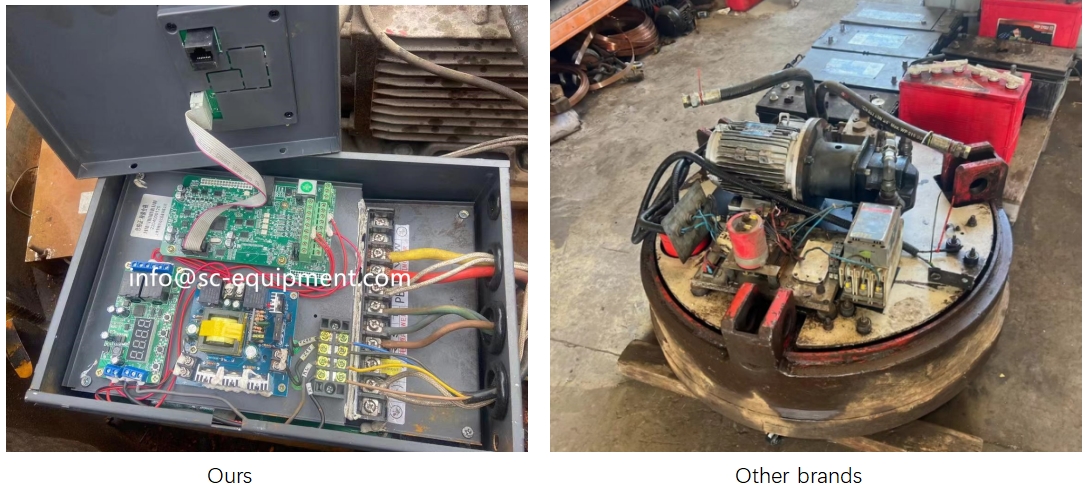

3, The integrator of SC brand of magnet (marked in red) uses a Variable Frequency Drive(VFD), which offers high stability and includes a power-off protection function. This effectively protects the motor and significantly reduces the failure rate. Other brands adopt On/Off Control. Below is the differences of them for your reference.

Variable Frequency Drive (VFD)

Principle of Operation: VFD technology adjusts the motor’s speed by varying the power supply frequency, enabling precise control over the equipment’s operational state.

Energy Efficiency: VFD systems are typically more energy-efficient as they modulate power output based on actual demand, thereby minimizing unnecessary energy consumption.

Comfort: VFD systems operate more smoothly, offer more accurate temperature control, and produce less noise, enhancing user experience.

Longevity: The gradual start and stop processes of VFD systems reduce mechanical wear and tear, generally resulting in a longer lifespan.

Cost: While the initial cost of VFD systems is higher, their energy-saving capabilities and extended lifespan can lead to lower long-term costs.

On/Off Control

Principle of Operation: On/Off control operates by simply switching the equipment on or off. When the set temperature or other parameters are reached, the device shuts down completely; it restarts when needed.

Energy Efficiency: On/Off systems consume more energy during the frequent start and stop cycles, making them less efficient.

Comfort: Temperature control in On/Off systems is less precise, often leading to significant temperature fluctuations and a poorer user experience.

Longevity: Frequent cycling causes greater mechanical wear and tear, resulting in a shorter lifespan for On/Off systems.

Cost: Although the initial cost of On/Off systems is lower, their reduced efficiency and shorter lifespan can lead to higher long-term costs.